Operational Excellence

Embracing change, always learning, everyone moving forward ready for “what’s next.”

Systems and Capabilities

that Scale

Our drive for operational excellence is reflected in part through our investments in cutting edge software, including a robust Digital Product Definition (DPD) dataset management system as well as thousands of training hours in ERP optimization, cyber-security, skills training, and more. These systems-capabilities make scaling the world’s most demanding parts, possible.

Individual Empowerment

The heart of our success at Camcraft is our staff— approximately 300 highly skilled and motivated team members in two Chicago-area facilities. By providing extensive continuous improvement and advanced education classes, our people have the tools to excel professionally. Once our customers experience this, they quickly become our biggest advocates.

As a way of empowering and engaging all our employees, Camcraft launched our E2B2 initiative – Everybody, Everyday (getting) Better and Better. Our culture of continuous improvement gives freedom and resources to every employee to close gaps between our current and desired state, producing over 50,000 implemented improvements since 2012. This type of individual and team responsibility creates a safer environment, and a more engaged workforce, allowing Camcraft to be more productive and able to deliver higher levels of quality on-time, every day.

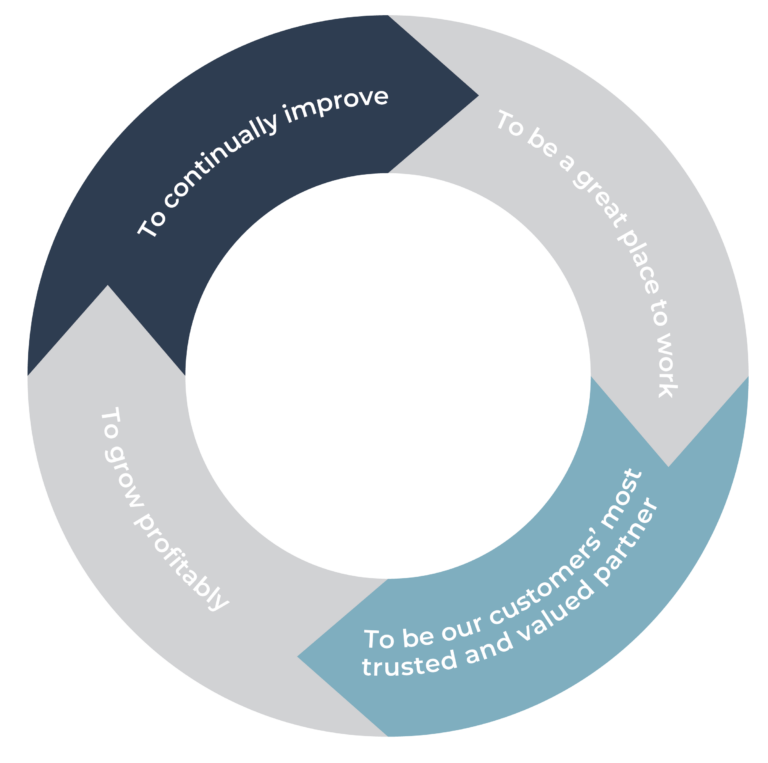

our objectives