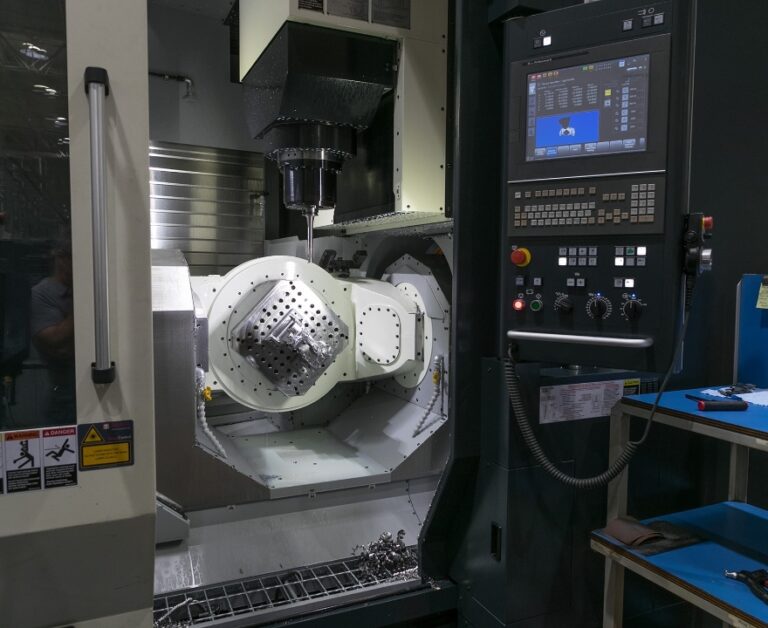

Prototyping

Tough Questions Asked

And Answered

NEW PRODUCTS, DEVELOPED WITH OUR PROVEN PROCESS

NP360 is a robust proven methodology of bringing programs to life. Customers engage our industry-leading project launch team when they need high levels of engineering, with significant investment in new assets, and a final product that meets strict schedule and quality demands. Let us show you how NP360 is different.

Where Designs go

to Graduate

Launching a robust manufacturing process can be significantly improved when prototyping is used to gauge a real world environment on critical design, metrology and manufacturing elements. Only when this work is done with rigor and precision can we feel confident that we have a bedrock print that will allow for a successful launch, ready to achieve cost, warranty, and performance targets. Experience the difference NP360 brings to your most intimidating machined part designs. Have confidence knowing what you see in development will be delivered in production.