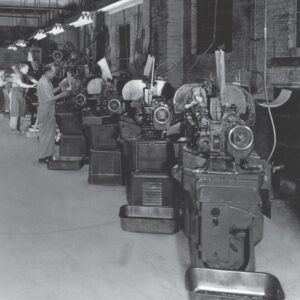

History

A HISTORY OF GROWTH IN THE PRECISION MACHINED PARTS INDUSTRY

Camco Founded

Bud Hawley opens Camco on North Avenue in Chicago.Camco becomes Camcraft

Camcraft Expands

Camcraft Expands

Camcraft moves to Franklin Park

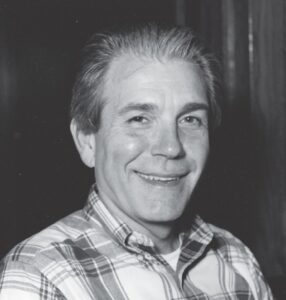

New Owner

Bern and Jeanne Bertsche purchase Camcraft in December 1986 from Olive Hawley

Market Focus

Camcraft focuses on the mobile hydraulics market. Success in this market leads to a significant transformation of Camcraft’s customer base, moving us forward into hydraulic automotive applications and subsequently into high-pressure diesel fuel systems.

Camcraft Grows

Camcraft moves into its newly constructed headquarters in Hanover Park.

Employee Development

Employee Development

Camcraft initiates its formal technical training program. Basic Certification, Technical Certification, and Accredited Journeyman Apprenticeship Certification is awarded to employees who successfully complete the program.

Student Outreach

Student Outreach

Camcraft initiates its student outreach program for local fifth and sixth grade students from Parkwood Elementary School. This leans Bern and Jeanne to form Crossroads Kids Club as a way to continue building relationships with the community. Crossroads now meets weekly in over 45 schools New President

Mike Bertsche named president of Camcraft.

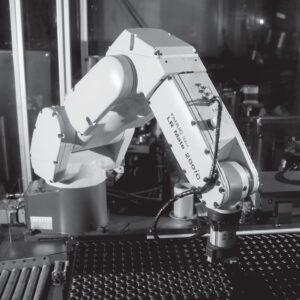

Increased Automation

Increased Automation

Automated inspection, assembly, and machine tending are added to meet our customers’ quality, cost, and production requirements. Our initial small steps into automation led to significant investments in automating processes throughout the company. Camcraft ultimately purchased Matrix, aimed at making robotic automation more accessible.

Investment Initiative

Investment Initiative

At the urging of a board member, the company begins an aggressive reinvestment initiative into the latest machine tools, metrology, and tooling in order to compete with the top firms in our industry world-wide.

Operational Excellence

Camcraft launches our E2B2 continuous improvement initiative in 2012. Everybody, Everyday, Getting Better and Better encourages and engages all of our employees to make our workplace safer, more productive, and helps us deliver the highest level of quality to our customers.